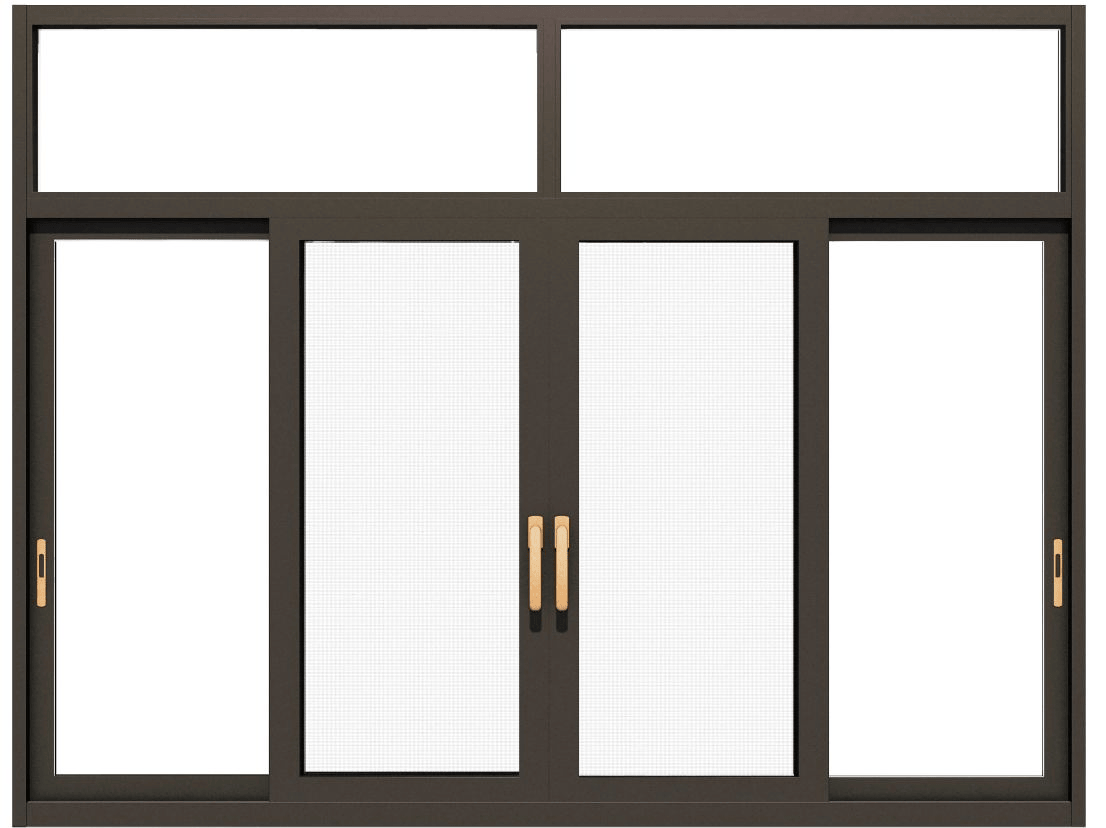

Global demand for 185 Heavy-Duty Sliding Doors has been on the increase to support modern concepts of construction involving durability, space optimization, and neat structural lines. This is inclusive of residential,commercial as well as industrial premise,s whereby such sliding doors can always be counted on for their strong attributes besides versatility plus reliability over long service life periods. Design trends, however have continued to favor flexibility in spatial organization, accompanied by minimalist detailing, thereby creating more market demand for high-quality heavy-duty sliding doors. This article thus forms a comprehensive discussion at different levels, ranging from materials used to engineering aspects concerning comfort through international applications describing what makes good quality 185 Heavy-Duty Sliding Doors.

Understanding the Concept of 185 Heavy-Duty Sliding Doors

185 is a specific structural category, profile dimension, or track rating (manufacturer’s standard), which means systems designed to carry large and heavy panels move smoothly and consistently. Such sliding doors are meant for places where ordinary door systems do not have enough strength, stability, or durability required in constant daily use. Heavy-duty sliding doors are found in industrial warehouses and cold storage as well as retail stores at farms of the new-age house concepts, logistics centers,s factories high commercial traffic areas! With increasing global construction standards, heavy-duty=long-lasting structure integrity has become an association that brings confidence to users worldwide.

Material Characteristics That Define Quality

High-grade aluminum or steel frames

185 Heavy-Duty Sliding Door frames are mostly made from either aluminum alloy or galvanized steel because the materials have great strength-to-weight ratios, corrosion resistance, and rigidity. Aluminum models are resistant to oxidation and maintain their sleek look; thus, suited for humid areas or coastal climates. Steel models carry with them an enormous capacity for impact resistance and stability in those environments that require maximum security and load-bearing strength.

Reinforced door panels

Panels may be tempered glass, laminated glass, insulated sandwich panels, multi-layer composites, or polycarbonate sheets and solid engineered materials, depending on the application. These choices of panels result in insulation, energy efficiency, and sound control, besides total weight. In industrial/cold storage applications, cores that are insulated maintain temperature stability inside the unit as well as ensure minimum energy loss.

Industrial-grade sliding tracks

Tracks count among the most vital elements in 185 Heavy-Duty Sliding Doors. Normally made from thickened aluminum or steel, they are engineered for smooth action and also to provide resistance against wear. The track system is so strong that it allows easy gliding of even extremely heavy panels and ensures their alignment over years and years of use.

Heavy-duty rollers and bearings

Rollers for 185 Heavy-Duty Sliding Doors use stainless steel bearings. Either nylon-coated wheels or precision-machined metal cores support smooth gliding under high loads with minimum friction. Because such doors are mostly used in places where frequent opening and closing are required, the durability of rollers measures long-term performance accordingly.

Advanced surface treatments

Powder coating, anodizing, galvanization, and UV-resistant finishes protect the structure from corrosion, fading, and weather damage. These treatments are especially important for outdoor installations or dusty and humid industrial environments.

Functionality and Performance

Smooth operation under heavy loads

A defining characteristic of 185 Heavy-Duty Sliding Doors is their ability to function smoothly even when the door panels are wide, tall, or exceptionally heavy. Precision-engineered rollers and tracks minimize resistance and ensure consistent movement.

Space-saving architectural design

Sliding doors maximize indoor space because they do not swing outward like traditional hinged doors. In dense industrial facilities, large retail spaces, and modern residential interiors, this efficiency supports better organization and more fluid movement.

Enhanced safety features

Features such as anti-jump systems, controlled soft-closing mechanisms, durable locks, and shatter-resistant materials improve safety. In environments with high foot traffic, workplace machinery, or temperature-controlled areas, safety components play a critical role.

Weather resistance and insulation

For exterior applications, 185 Heavy-Duty Sliding Doors often include weatherstripping, thermal breaks, and water-resistant seals. These components enhance energy efficiency and protect interior spaces from wind, moisture, and temperature changes.

Comfort and User Experience

Noise reduction

Heavy-duty structures, insulated panels, and tight seals reduce noise transfer and operational sound. This improves comfort in residential areas, commercial environments, and industrial workplaces where acoustic control contributes to productivity.

Smooth gliding feel

Even when supporting significant weight, well-designed 185 Heavy-Duty Sliding Doors move effortlessly. This enhances user comfort, especially in settings where the doors are opened many times throughout the day.

Easy customization

The doors can be customized in size, build material, panel type, transparency, finish, and locking mechanism. This flexibility supports regional climate needs, cultural design preferences, and functional requirements across global markets.

Global Applications of 185 Heavy-Duty Sliding Doors

Industrial manufacturing

Factories use heavy-duty sliding doors to divide production zones, secure equipment rooms, and separate temperature-controlled areas. Their strength and smooth operation make them ideal for demanding industrial workflows.

Commercial spaces

In shopping centers, corporate offices, showrooms, and supermarkets, 185 Heavy-Duty Sliding Doors serve as large entrances, storeroom access points, and flexible partitions. Their modern appearance complements commercial architecture, enhancing brand image and spatial organization.

Residential architecture

Increasingly, homeowners choose these sliding doors for patios, balconies, open-plan interiors, closets, and room partitions. Their ability to create seamless transitions between spaces contributes to bright, modern, and visually open home layouts.

Agriculture and livestock environments

These doors are used in barns, storage structures, and agricultural facilities due to their durability, ventilation options, and ease of operation, even when exposed to dust, moisture, or outdoor conditions.

Logistics and cold storage

Temperature-regulated facilities rely on insulated 185 Heavy-Duty Sliding Doors to maintain stable climate conditions. Their robust sealing and insulated cores reduce energy consumption and protect stored goods.

Durability and Long-Term Reliability

Corrosion resistance

Coated steel and anodized aluminum materials ensure that 185 Heavy-Duty Sliding Doors maintain long-term structural integrity even in coastal or humid climates.

Load-bearing strength

These sliding doors are engineered to support large panel sizes and continuous use. Reinforced tracks and precision rollers minimize the risk of deformation over time.

Temperature resistance

Heavy-duty materials prevent warping or mechanical failure caused by extreme heat, freezing temperatures, or rapid temperature fluctuations.

Low maintenance requirements

Their robust design means maintenance is usually limited to cleaning tracks and occasional inspections. This makes the doors a cost-effective long-term investment.

Architectural Flexibility and Design Potential

Modern architecture creates open space, lets light in, and allows areas to be used for more than one purpose. 185 Heavy-Duty Sliding Doors support these aspects of design by permitting:

• Large transparent facades

• Smooth indoor-outdoor transitions

• Multi-panel sliding systems

• Minimalist interior partitions

• Hidden or recessed track designs

• Automated opening systems

They associate very well with different architectural styles, therefore suitable for both modern and traditional buildings.

Environmental and Energy Considerations

Heavy-duty sliding doors play a role in the green global construction boom. Buildings can be made more energy efficient with artificial dependency lighting reduced inside, recyclable content available materials used to manufacture and supply long service life waste material insulated, thermally broken heavy duty sliding doors consume hvac cost regulate indoor temperature.

Why Their Global Popularity Continues to Grow

Urbanization and industrialization-185 Heavy-Duty Sliding Doors are being increasingly used all over the world,• Commercial construction is on the rise,-because of flexibility in partitioning spaces within residences,-Logistics and cold chain markets & Modern architects’ preferences for a strong yet lightweight economical solution to durability!

This happens when products provide exactly what consumers want, together with some extra advantages such as visual appearance (aesthetics) or any other secondary function. That is why they have become baseline preferred options by different sectoral businesses around the continents.

Conclusion

185 Heavy-Duty Sliding Doors are smooth operators under heavy loads. They maximize interior space. Their minimalist hardware suits the latest architectural trends while delivering a tough, consistent performance in demanding environments. Customizable by material and finish options engineered for weather resistance with high levels of insulation, these sliding doors will continue to be specified in residential, commercial, industrial agricultural buildings worldwide as long as the global demand trend upward, because that means more opportunity for architectural innovation involving them as an essential component of modern construction.